Recipe Precision. Automated Compliance.

Your Recipe is More Than a Formula. It’s a Compliance Asset.

Your recipe is the nexus of product quality, safety, and regulatory compliance. Managing formulas, processes, and subsequent nutritional data in fragmented tools leads to errors, rework, and compliance risk. Fulvisol’s Recipe Management moves beyond basic formulation to deliver a holistic, instruction-driven system that guarantees nutritional accuracy and regulatory certainty from concept to finished goods.

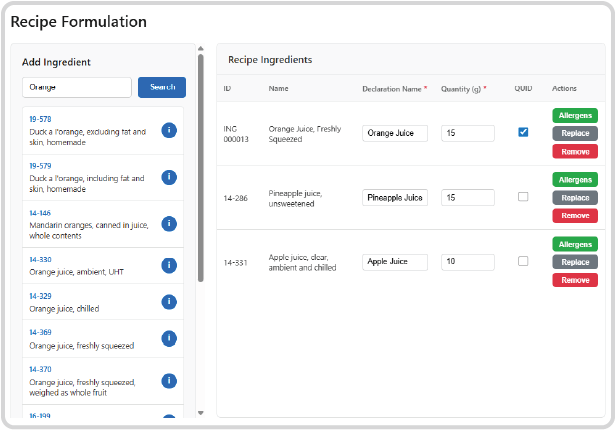

Intelligent Formulation & Layered Ingredient Roll-up

Accelerate prototyping while establishing a foundational data structure that scales from concept to commercialisation.

Rapid Prototyping with CoFID:

Jumpstart formulation by using nutritional values from established databases like the Composition of Food Integrated Dataset (CoFID) as placeholder ingredients. This allows for immediate, accurate nutritional estimates during the ideation phase.

Custom Ingredient Design:

Seamlessly transition to production-ready data. Define your own ingredients by rolling up nutritional values from the base Raw Materials provided by suppliers. You control the relative composition, ensuring all supplier-provided data is accurately reflected in your final ingredient profile.

Foundational Compliance:

Define critical recipe data at the source, including QUID (Quantitative Ingredient Declaration) and comprehensive Allergen presence, ensuring these non-negotiable details are accurate before processing even begins.

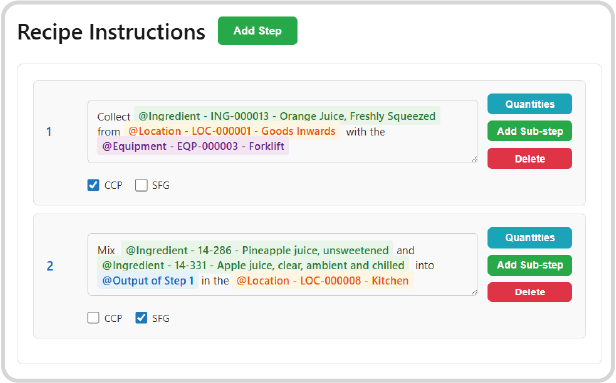

Dynamic Process Control & Connected Manufacturing

The physical transformation of a product requires structured management. Fulvisol connects your recipe instructions directly to the production environment, ensuring repeatability and control.

Step-by-Step Instructions:

Structure your recipe into clear, actionable, process-driven steps. Define specific quantities used at each stage, ensuring repeatability and control.

Connected Manufacturing:

Link each instructional step directly to the managed Locations and Equipment (e.g., specific Ovens, Mixers, or Preparation Areas) within your facilities. This integration removes ambiguity for operators and links production steps directly to physical assets for auditing.

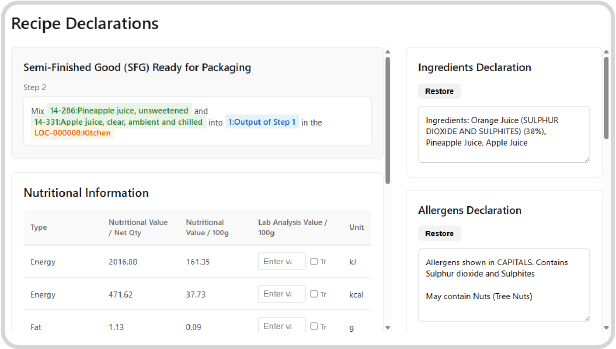

Generative Declarations & Nutritional Precision

Trust your data. Fulvisol ensures that the nutritional information on your label reflects the reality of your process, not just the sum of raw ingredients.

Model the Physical Reality (Cook Loss):

Accurate declarations require accounting for physical changes. Specify and apply Cook Losses (like moisture evaporation or fat rendering) to automatically recalculate nutritional values at every step.

Automated Declaration Generation:

The final process step is marked as the Semi-Finished Good (SFG). These physically corrected values – having accounted for the cook loss – become the definitive source for generating all your product declarations, ensuring absolute alignment between the lab and the label.

Automated Regulatory Certainty & Claims Identification

Move beyond manual checking. Let Fulvisol’s engine validate your final product data against global standards instantly.

Instant Compliance Audits:

The system performs automated, real-time regulatory checks across multiple dimensions before any product is finalised:

– Food Safety Regulations

– Ingredient Compliance Checks

– Allergen Regulations

– Nutritional Claims & Regulations (automatically identifying eligible claims based on verified nutritional content).

Interested in seeing what Fulvisol Food + Beverage could do for your business?

Streamline the transition from R&D and pilot production to full-scale manufacturing

By submitting this form I agree to my details being used in sole connection with the intended enquiry. Please check our privacy policy to see how we protect and manage your submitted data.