Unify Facilities, Supply Chain, and Sustainability

From Floor Plan to Global Footprint: Operational Clarity at Scale.

Product safety and time-to-market depend not just on what you make, but where and how you make it. Fulvisol’s Facility Management features bridge the gap between your physical operations, internal teams, and global supply chain, ensuring granular control, operational compliance, and essential sustainability tracking—all within your single PLM environment.Business Unit Hierarchy: The Core Operational Record

Establish a precise digital representation of your organisational structure and associated compliance data.

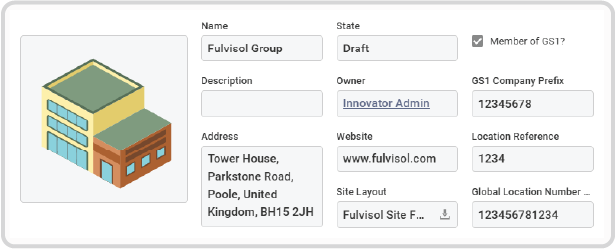

Integrated GS1 & Identity Data:

Define your top-level Business Units (e.g., manufacturing sites, distribution hubs), capturing essential identity details like GS1 location keys and associated regulatory information.

Structured Relationships:

Clearly map related entities, including Sub-Business Units (e.g., specific departments or production lines), Approved Suppliers, and assigned Team Members.

Controlled Access:

Team member roles defined here dictate access rights to the specific locations, equipment, and sensitive processes managed by that Business Unit, enforcing security and compliance from the ground up.

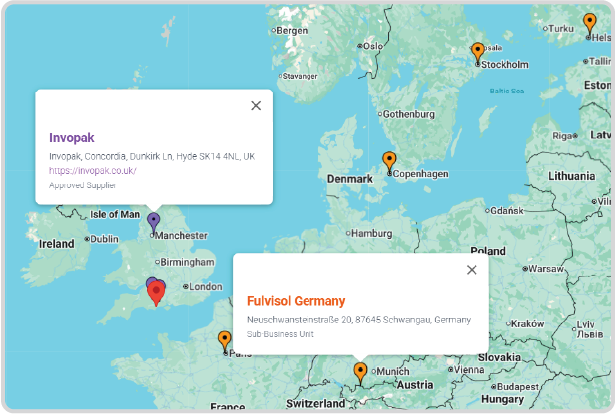

Geospatial Visibility: The Global Operations Map

Gain immediate, critical clarity on your entire operational ecosystem, visualised on a live map interface.

Pinpoint Precision:

View all related entities – your main Business Units, their Sub-Business Units, and all Approved Suppliers – as interactive pins on a single, responsive map.

Supply Chain Resilience:

Quickly identify geographical concentrations of suppliers or production sites, aiding in risk assessment (e.g., natural disaster exposure) and logistics planning.

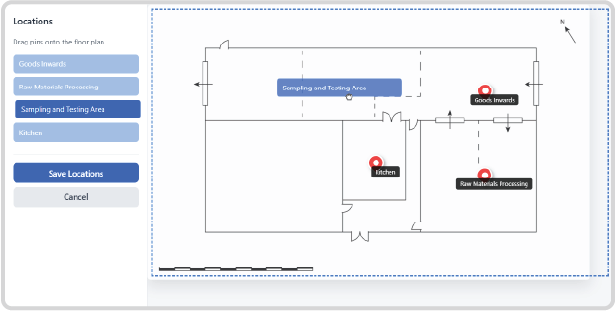

Granular Site Control: The Digital Floor Plan

Move beyond building names to manage the physical layout and equipment location within each facility.

Site Layout Integration:

Upload the digital layout or site plan for your Business Unit. This visual bedrock links physical space to digital information.

Drag-and-Drop Location Mapping:

Easily define and place specific functional Locations (e.g., Kitchen Prep Area, Ingredient Storage, Quality Control Lab, Equipment Washing Bay) directly onto the floor plan using an intuitive drag-and-drop tool.

Process Referencing:

Once mapped, these specific Locations and the Equipment housed within them become live reference points, ensuring that Instructions, SOPs, and Process Workflows can directly reference where an action must be performed, dramatically reducing ambiguity and errors on the factory floor.

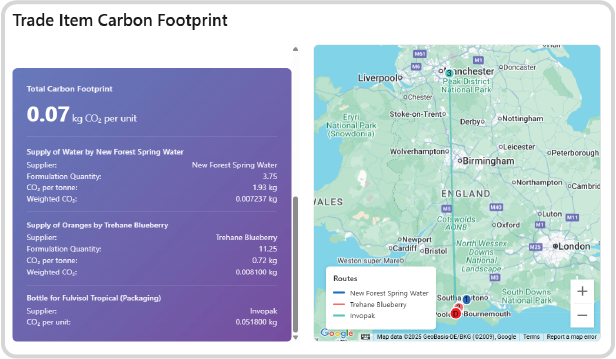

Sustainability & Compliance: Automated CO2 Tracking

Leverage unified location data to introduce crucial sustainability metrics into your product development cost model.

Automated CO2 Calculation:

Because the system holds the precise locations of all Business Units, Sub-Business Units, and Suppliers, Fulvisol automatically calculates accurate transit CO2 emissions for ingredient and product shipments.

Freight Mode Analysis:

Easily select and compare emissions based on the transport method used (Road, Rail, Sea, or Air freight), empowering sustainable sourcing decisions and feeding verifiable data into your corporate ESG reporting.

Interested in seeing what Fulvisol Food + Beverage could do for your business?

Streamline the transition from R&D and pilot production to full-scale manufacturing

By submitting this form I agree to my details being used in sole connection with the intended enquiry. Please check our privacy policy to see how we protect and manage your submitted data.